Key Takeaways

- CNC mills use computer-controlled automation to shape metal, plastic, and wood with high precision and efficiency.

- Key components include the control unit, worktable, spindle, automatic tool changer, and multi-axis drives, enabling complex 3D operations.

- CNC milling stands out for its ability to produce parts with tight tolerances and repeatable accuracy, essential for industries like automotive, aerospace, and medical devices.

- Programming with specialized software allows CNC mills to convert digital designs into consistently manufactured physical parts.

- Automation boosts efficiency, reduces human error, and ensures consistent quality across large production runs.

CNC mills use computer-controlled automation to precisely shape metals, plastics, and wood by following programmed instructions that guide cutting tools through complex movements. These machines achieve exceptional accuracy with tolerances as tight as ±0.01mm, making them essential for automotive, aerospace, and medical manufacturing applications. The automated process eliminates human error whilst delivering consistent results across large production runs. Leading precision manufacturers like Yijin Hardware CNC milling services support critical industries requiring reliable, high-quality components.

Understanding CNC Milling

CNC milling uses automated controls to guide precision tools in shaping parts from raw material blocks. Manufacturers select CNC mills to produce components with complex features, tight tolerances, and repeatable accuracy—criteria crucial for industries like automotive, aerospace, and medical device manufacturing.

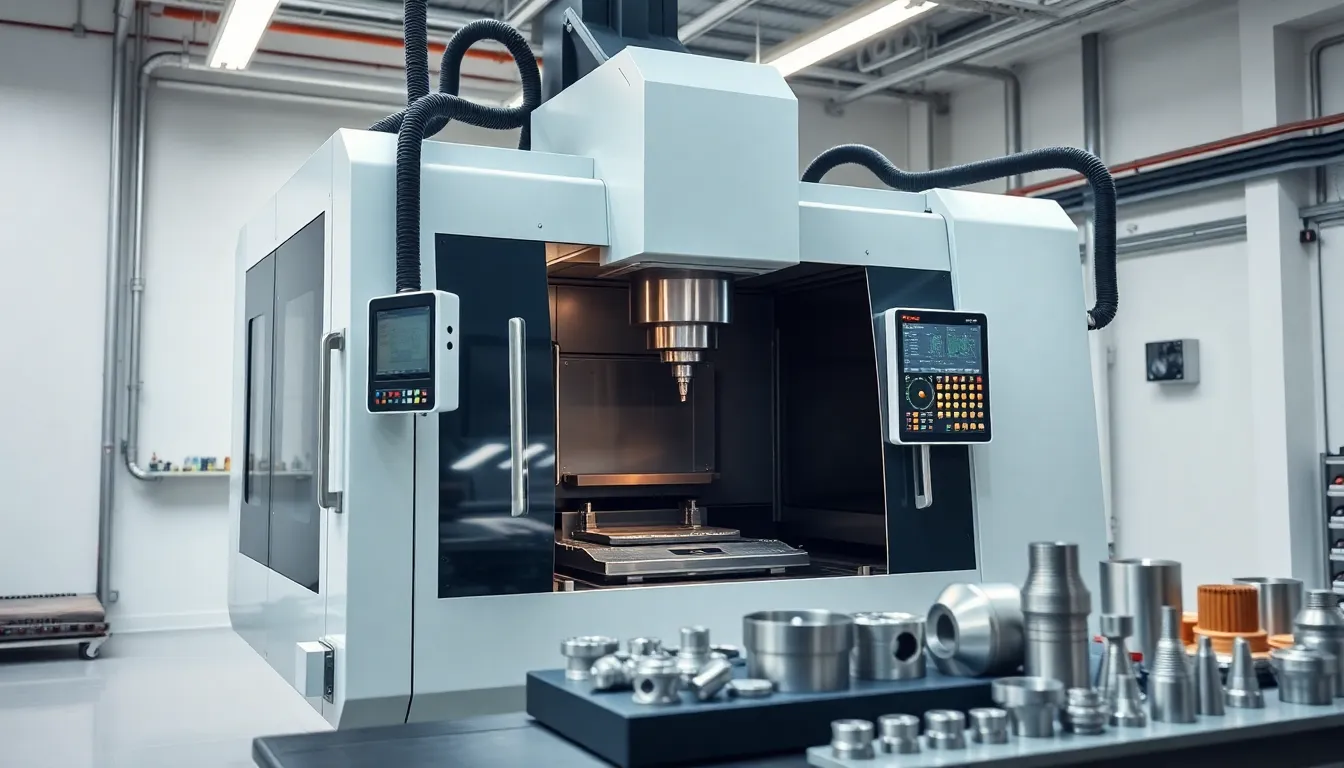

Key Components of a CNC Mill

Key components of a CNC mill include the control unit, worktable, spindle, tool changer, and axis drives. The control unit processes digital instructions, converting CAD models into machine movement sequences. The worktable holds raw material securely for stability during operations. The spindle rotates cutting tools at defined speeds, enabling cuts in metals, plastics, and woods. Automatic tool changers allow fast switching between tools, improving workflow efficiency. Axis drives (X, Y, and Z) enable multi-directional movement for 3D shaping. For example, Yijin Hardware in Homestead, FL uses advanced CNC mills configured with these features to deliver consistent, high-precision results for automotive and aerospace parts.

How CNC Mills Differ from Other Machines

CNC mills differ from manual mills and other CNC equipment in three main aspects: automation, complexity, and function. CNC mills execute programmed instructions for consistent outputs, while manual machines rely on operator skill for each cut. Unlike CNC lathes that revolve the workpiece for symmetrical objects, CNC mills keep materials stationary as cutting tools move along multiple axes. CNC routers, though somewhat similar, specialize in softer materials like plastics and wood, whereas CNC mills handle harder metals and alloys. By deploying these specialized capabilities, Yijin Hardware supports critical industries with distinctly manufactured parts, from custom fasteners to die-cast prototypes.

How a CNC Mill Works

A CNC mill operates by following programmed instructions that control its cutting tools and movement. This process enables precise material shaping for consistent part quality.

The Role of Computer Programming

Computer programming sets the precise commands a CNC mill follows during operation. Engineers use specialized software like G-code or CAD/CAM programs to define tool paths, cutting speeds, and material removal sequences. Each program translates a digital part design into instructions that guide the mill’s axis motions and spindle actions. Manufacturers input these files into the machine’s control unit, which executes the plan automatically. For example, Yijin Hardware uses advanced CAD/CAM integrations to support high-precision part production for automotive and aerospace clients in Homestead, FL.

Automation and Precision in Operation

Automation ensures a CNC mill completes each step independent of manual intervention once programming begins. Integrated sensors and servo motors maintain accurate tool positions, holding tolerances as tight as ±0.005 mm for components such as turbine blades and custom engine brackets. Systems monitor tool wear and alignment to optimize results during extended runs. Shops like Yijin Hardware rely on this automation to deliver multiple complex parts with identical specifications, reducing errors and boosting productivity across precision manufacturing projects.

Applications of CNC Milling

CNC milling applies precise automated machining to transform digital designs into finished parts. Industries depend on this process for repeatable accuracy and complex geometries that manual methods can’t achieve.

Common Industries Using CNC Mills

Manufacturers in the automotive sector use CNC milling to shape engine blocks, cylinder heads, and suspension components for consistent fit. Aerospace companies rely on CNC mills for turbine blades, landing gear, and airframe supports, demanding strict tolerances. Medical device makers machine implants, orthopedic components, and surgical tools from titanium and stainless steel for patient safety. Electronics producers use CNC milling to create heatsinks, enclosures, and connectors with fine features. Energy sector firms employ CNC mills to craft pump housings, turbine casings, and precise fittings. Companies like Yijin Hardware in Homestead, FL provide CNC milling to service these sectors, supporting innovation and reliability.

Typical Products and Parts Created

CNC mills create brackets, housings, enclosures, and panels for machinery and electronics. Cutting tools, dies, molds, and jigs come from rigid metals for manufacturing lines. Gears, shafts, flanges, and couplings fit high-stress applications in engines and motors. Medical implants, bone plates, and surgical guides require tight tolerances for compatibility. Prototype parts, custom fasteners, and small-batch components meet specifications for development and testing. Yijin Hardware produces these parts using CNC milling, delivering consistent quality and tight tolerances for automotive, aerospace, and medical OEMs.

Benefits of Using CNC Mills

CNC mills deliver measurable gains in quality and speed for precision manufacturing. Businesses like Yijin Hardware in Homestead, FL, use these benefits to support demanding projects for automotive and aerospace sectors.

Improved Accuracy and Consistency

CNC mills achieve tight tolerances, often within ±0.01 mm, through computer-controlled movements and automated feedback systems. Each part matches digital specifications without variation, unlike manual production lines where skill gaps can introduce inconsistencies. Integrated sensors and servo motors maintain accurate tool positioning, which ensures even intricate features remain consistent across hundreds of units. Yijin Hardware uses this capability to supply complex fasteners and housings that meet strict industry standards, eliminating costly errors. Automated calibration functions further reduce human error by continuously adjusting tool paths. Large orders for medical or aerospace parts see uniform quality and performance, regardless of batch size.

Enhanced Efficiency and Productivity

CNC mills reduce lead times and increase production speeds by automating the entire cutting and shaping process. Tool changers and multi-axis programming enable the machine to handle complex cuts or switch between operations in seconds, eliminating manual intervention. This automation leads to higher throughput, with some shops seeing production rates increase by 30–50%. Yijin Hardware integrates high-speed CNC equipment to deliver precision machining services on tight deadlines for clients in Homestead, FL. Machines can operate for extended periods without breaks, letting businesses process large batches overnight or combine different material types without pausing for manual adjustments. Digital monitoring and scheduling systems maximize machine utilization, reducing downtime and bottlenecks in busy manufacturing environments.

About Yijin Hardware

Yijin Hardware offers a range of precision manufacturing services, including CNC machining, sheet metal fabrication, and custom fasteners. They also provide additional solutions such as die casting, injection molding, and 3D printing to support various industries like automotive, aerospace, medical, and energy. Whether it’s a complex machined component or a custom manufacturing solution, they are equipped to deliver high-quality results for diverse industrial applications.

Contact:

Gavin Yi, CEO

Phone: +1 626 263 5841

Email: [email protected]

Website: yijinsolution.com

Location:

760 NW 10th Ave, Homestead, FL 33030

Frequently Asked Questions

What is a CNC mill?

A CNC mill is a computer-controlled machine that uses precise movements to cut and shape materials like metal, plastic, and wood. It follows programmed instructions for automated, accurate, and repeatable manufacturing of complex parts.

How does a CNC mill differ from a manual mill?

A CNC mill operates automatically by following programmed instructions, ensuring consistent and precise results. In contrast, a manual mill relies on the operator’s hands and skill, making it less consistent and more prone to human error.

What materials can CNC mills work with?

CNC mills can process a wide range of materials, including metals (like aluminum and steel), plastics, and wood. Their versatility makes them essential in manufacturing for various industries.

What industries use CNC milling?

CNC milling is widely used in automotive, aerospace, medical, electronics, and energy industries. It’s key for producing precision components such as engine blocks, turbine blades, and medical tools.

What are the main components of a CNC mill?

Key components of a CNC mill include the control unit, worktable, spindle, tool changer, and axis drives. These parts work together to automate, stabilize, and ensure accurate machining operations.

How accurate are CNC mills?

Modern CNC mills can achieve tolerances as tight as ±0.01 mm, thanks to automated controls and integrated sensors. This ensures each finished part meets strict quality and safety standards.

What are the benefits of using CNC milling?

CNC milling enables high precision, consistent quality, fast production, and reduced errors. Automation increases productivity, allowing businesses to produce complex parts efficiently and reliably.

How does a CNC mill’s automation work?

Automation in CNC milling uses computer programs (like G-code or CAD/CAM software) to control tool movements, speeds, and tool changes. Integrated sensors and feedback systems maintain accuracy and consistency during operation.

What types of products are made with CNC milling?

Products made with CNC milling include gears, engine components, brackets, housings, custom fasteners, and more. These items often require precise shapes and tight tolerances for proper function.

Why is CNC milling important for precision manufacturing?

CNC milling is crucial for precision manufacturing because it provides repeatable accuracy, complex shaping, and reliable output. This ensures components meet the stringent standards required in critical industries.