Key Takeaways

- Double-sided PCB assembly manufacturers enable higher component density and circuit complexity by placing components on both sides of the board, ideal for compact and powerful electronic devices.

- These assemblies support advanced applications across consumer electronics, industrial equipment, medical devices, automotive electronics, and telecommunications.

- Choosing a reliable manufacturer requires attention to experience, industry certifications (such as ISO 9001), and robust quality assurance practices like AOI and X-ray inspection.

- Leading manufacturers, like WellPCB, offer customization, engineering support, and rapid prototyping, ensuring assemblies meet project-specific requirements.

- Double-sided PCB assemblies contribute to cost-effective production, improved performance, and efficient use of space, driving innovation in modern electronics.

Double-sided PCB assemblies enable higher component density and enhanced circuit complexity by mounting electronic components on both sides of the board, making them ideal for compact consumer electronics, industrial equipment, and medical devices. These assemblies offer cost-effective manufacturing solutions whilst supporting sophisticated circuit routing and miniaturisation requirements. Leading double-sided pcb assembly manufacturer companies provide automated assembly processes, rigorous quality control, and comprehensive engineering support for diverse electronic applications.

What Is Double-Sided PCB Assembly?

Double-sided PCB assembly involves placing electronic components on both the top and bottom surfaces of a printed circuit board. This layout supports complex circuit routing and enables higher component density than single-sided PCBs. Assembly processes use through-hole and surface-mount technologies to join resistors, capacitors, and integrated circuits on each side. Double-sided PCBs are common in applications with limited space and high functionality requirements, such as power supplies, industrial controls, and consumer products.

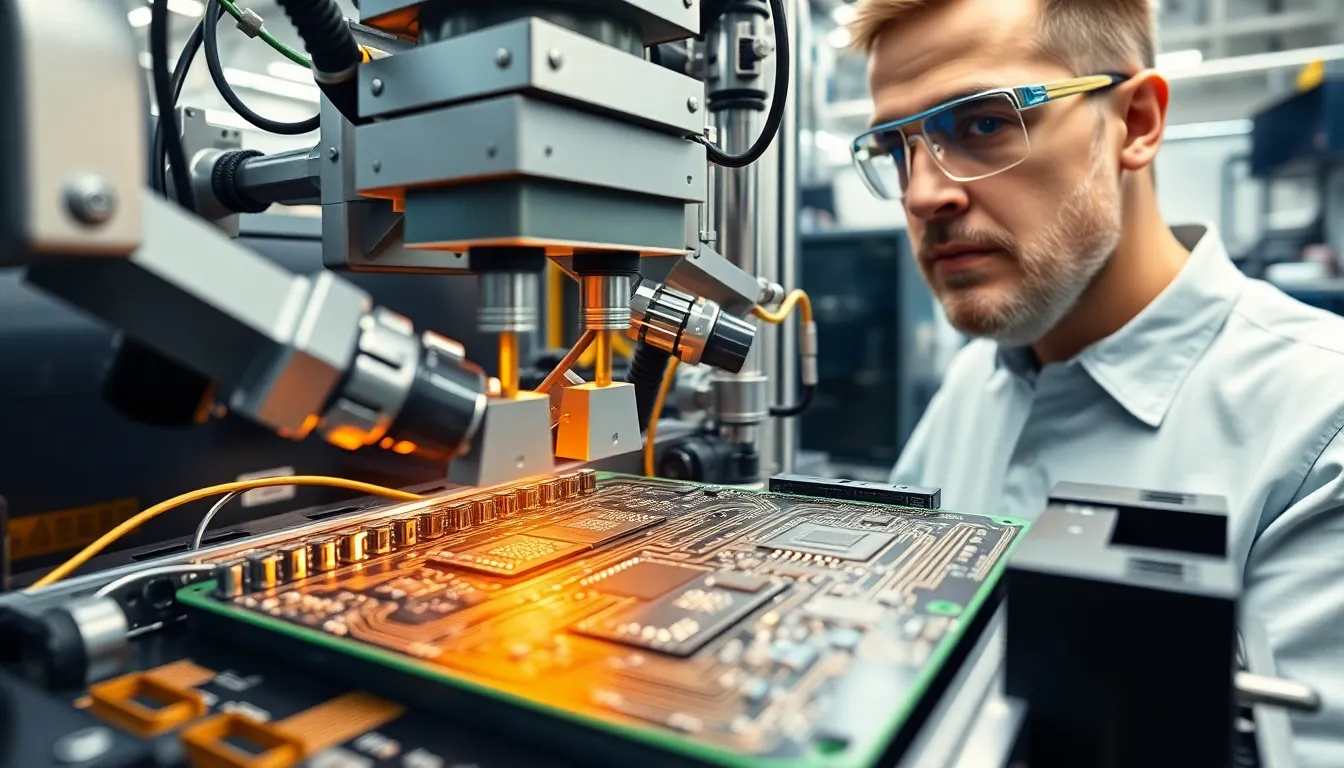

WellPCB, a manufacturer based in China, offers double-sided PCB assembly using automated placement machines and rigorous inspection protocols. Their capabilities include solder paste printing, automated optical inspection, and X-ray inspection for quality control. Orders from WellPCB include production that meets international standards, with quick turnaround times to support global customers seeking efficient double-sided PCB solutions. These assemblies improve performance in compact designs without sacrificing electrical reliability.

Key Benefits of Double-Sided PCB Assemblies

Double-sided PCB assemblies support advanced electronics by allowing component mounting on both sides of the board. They enable dense circuit design, high performance, and efficient use of space in modern electronic products.

Increased Component Density

Double-sided PCB assemblies enable higher component density compared to single-sided designs. By placing electronic parts such as resistors, capacitors, and integrated circuits on both the top and bottom layers, manufacturers achieve more compact layouts. This efficient use of space supports miniaturization in devices like smartphones, industrial control units, and power modules. WellPCB uses automated placement machines to position components precisely on both surfaces, reducing board size without sacrificing functionality. Increased density makes double-sided assemblies suitable for products that require high functionality in limited physical dimensions.

Enhanced Circuit Complexity

Double-sided configurations allow for more complex circuit routing and sophisticated functions. Engineers can design multilayer connections using vias, which link the top and bottom layers for greater flexibility in trace routing. This complexity supports features like signal isolation, power management, and multiple signal paths in the same board. Applications such as medical devices, automotive electronics, and telecommunications equipment rely on these assemblies for reliable, intricate circuitry. WellPCB employs advanced manufacturing and inspection protocols to ensure each assembly meets precision and reliability standards even for detailed or demanding circuit designs.

Cost-Effectiveness in Manufacturing

Double-sided PCB assemblies offer cost-effective solutions for medium and high-volume production. By allowing more circuits in a smaller footprint, these boards reduce the overall material required for each device. Shorter trace lengths and fewer interconnections also lower assembly complexity and the need for additional wiring or connectors. WellPCB achieves economies of scale by combining automated processes with stringent quality controls, resulting in faster turnaround times and lower manufacturing costs. Electronics manufacturers benefit from reduced unit prices and consistent product quality, especially in high-demand sectors like consumer electronics and industrial systems.

How to Choose the Right Double-Sided PCB Assembly Manufacturer

Selecting a double-sided PCB assembly manufacturer impacts product performance and production timelines. Reliable providers combine specialized experience, rigorous quality standards, and responsive support for engineering requirements.

Experience and Industry Certifications

Relevant experience and recognized certifications indicate a manufacturer’s reliability. Leading double-sided PCB assembly manufacturers consistently produce complex assemblies for sectors like automotive, medical, and industrial controls. Certifications such as ISO 9001 or IPC-A-610 prove compliance with international standards. WellPCB operates with over 10 years of PCB assembly experience and holds ISO 9001, IATF 16949, and ISO 14001 certifications. Suppliers with documented industry qualifications show capability in meeting demanding design and regulatory requirements.

Quality Assurance and Testing Capabilities

Comprehensive quality management and advanced testing technology maintain consistent assembly reliability. Top manufacturers employ processes such as Automated Optical Inspection (AOI), X-ray inspection, and In-Circuit Testing (ICT) during double-sided PCB assembly. WellPCB integrates multi-stage inspection—including AOI, ICT, and Functional Testing—to ensure defect-free boards before shipping. Robust traceability systems document all manufacturing steps and test records for each lot. These capabilities reduce the risk of failures in high-reliability devices.

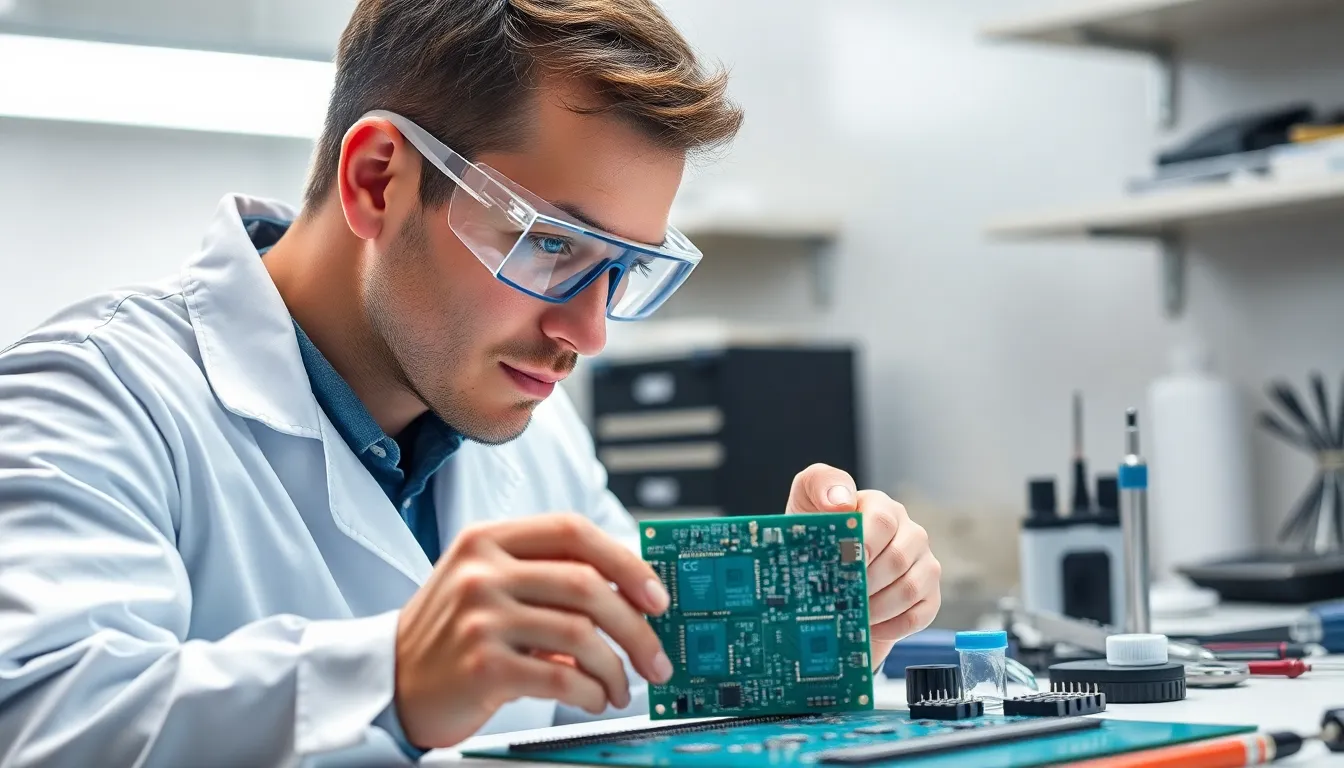

Customization and Engineering Support

Responsive customization and engineering support adapt assemblies to project-specific needs. Leading manufacturers, including WellPCB, collaborate on PCB layout, material selection, and component sourcing. Dedicated engineering teams assist with design for manufacturability (DFM) reviews and offer solutions for space constraints or high-density routing. Flexible prototyping services and rapid iteration cycles support smooth transition from design to mass production. Strong technical support simplifies integration and improves time to market for new electronics products.

Common Applications of Double-Sided PCB Assemblies

Double-sided PCB assemblies support a wide range of electronics that demand compact size and higher circuit complexity. In consumer electronics, manufacturers apply double-sided PCBs in smartphones, tablets, LED lighting, and wearable devices. Each device relies on high component density and reliable signal performance.

Industrial equipment uses double-sided PCB assemblies to enable advanced control systems, automation modules, and power management units. These PCBs withstand high temperatures and mechanical stress, critical for performance in factory environments or heavy machinery.

Medical devices depend on double-sided PCB assemblies for diagnostic instruments, portable monitors, and imaging systems. These applications require compact layouts and precise circuit routing to ensure patient safety and accurate readings.

Automotive electronics, such as engine controllers, infotainment centers, and sensor modules, rely on double-sided PCBs to fit electronics into tight spaces and support robust functionality for vehicle safety and efficiency.

Telecommunication systems, including routers, network switches, and wireless modules, incorporate double-sided PCBs to manage high-speed data transfer and optimize signal integrity in compact enclosures.

WellPCB, based in China, produces double-sided PCB assemblies for these applications using automated SMT lines, AOI inspection, and rapid turnaround, ensuring global customers receive consistent quality and reliable performance.

About WellPCB

WellPCB is a global PCB manufacturing company providing comprehensive printed circuit board solutions and assembly services. With manufacturing facilities across multiple continents, they offer high-quality PCB production, design support, and assembly services to meet diverse electronic manufacturing needs. Whether it’s prototype development or large-scale production, they are equipped to deliver reliable PCB solutions with international manufacturing capabilities and quality standards.

Contact:

Hommer Zhao, Director of Sales and Marketing, Co-founder

Phone: (424) 842-2783

Email: [email protected]

Website: wellpcb.com

Locations:

3826 Medford St, Los Angeles, CA 90063, USA

Frequently Asked Questions

What is a double-sided PCB assembly?

A double-sided PCB assembly is a printed circuit board that has electronic components mounted on both the top and bottom surfaces. This design allows for more complex circuitry and higher component density compared to single-sided PCBs.

What are the main benefits of double-sided PCB assemblies?

Double-sided PCB assemblies offer compact layouts, higher component density, and support for complex circuit routing. They enable more advanced, space-efficient electronics and are cost-effective for medium and high-volume production.

In which applications are double-sided PCBs most commonly used?

Double-sided PCBs are widely used in consumer electronics (like smartphones, tablets, and wearables), industrial equipment, medical devices, automotive electronics, and telecommunication systems that require compact size and sophisticated circuits.

How does double-sided PCB assembly support miniaturization?

By accommodating components on both sides, double-sided PCB assemblies allow more parts to fit in a smaller area. This is essential for modern electronics that need to be smaller yet more powerful.

What technologies are used in double-sided PCB assembly?

Double-sided PCB assembly commonly uses surface-mount technology (SMT) and through-hole technology to attach components on both sides of the board, enabling complex and reliable designs.

How do I choose the right double-sided PCB assembly manufacturer?

Look for manufacturers with extensive experience, relevant industry certifications (like ISO 9001), robust quality assurance processes, customization support, and advanced inspection methods such as AOI and ICT.

Why is quality assurance important in double-sided PCB assembly?

Quality assurance ensures the assembled PCBs are free from defects and perform reliably. Advanced inspection methods like Automated Optical Inspection (AOI) and In-Circuit Testing (ICT) are critical for verifying assembly quality.

How does automation improve double-sided PCB assembly?

Automated machines ensure precise component placement, consistent quality, and faster production times, reducing errors and enhancing overall efficiency in manufacturing double-sided PCB assemblies.

What are the cost advantages of using double-sided PCB assemblies?

Double-sided PCB assemblies reduce material consumption and assembly steps, making them more cost-effective, especially in medium and high-volume production runs, while delivering reliable performance.

What services does a leading manufacturer like WellPCB offer?

WellPCB provides double-sided PCB assembly with advanced automation, rigorous quality inspection, fast turnaround times, customization options, and engineering support such as design for manufacturability (DFM) reviews.